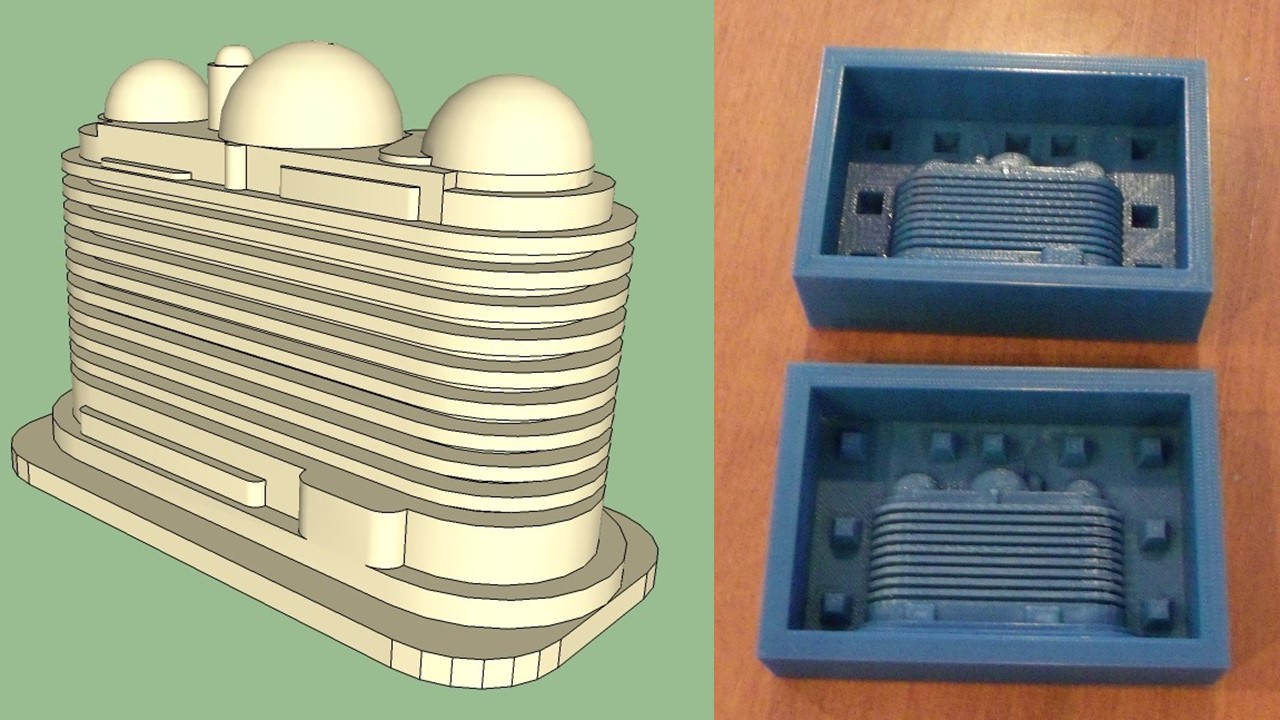

For those of you who are interested in how to make a two part master mold out of a 3d model, it is actually rather simple (in theory). This article assumes that you already have the basic mold making, casting, and CAD skills necessary to complete this process and will concentrate on combining the skills together. First you have to have a completed model. This model must be a solid and can’t have any mistakes in it. If you weren’t meticulous while making your drawing, this part can be a real pain. It helps if you have already designated all surface orientations, but isn’t necessary yet. For this example I will use my drawing of a scifi transformer.

The next step is to add the part line. Making a mold is all about the part line. This is the portion that makes or breaks a mold so it is important that you understand how to do it properly. If you are familiar with the method of embedding an object in clay to make a two part mold, this should be very easy for you to understand. The outer rectangle in this case will eventually be used to form the side walls with so it is substantially easier if this is all on the same plane. The rest of the part line can be as convoluted as it needs to be so long as everything matches up and forms a continuous surface. Any alignment lugs, air vents, sprues, ect should be added at this point.

Next make a duplicate copy of the model along with the part line and then erase everything on one side of the part line. Do this to both copies of the model but on opposite sides. The part line must remain identical on both copies or the finished halves of the mold won’t match up properly.

Now extend the sides up high enough to contain enough material to make a mold, and extend the bottom down far enough to make the master mold sufficiently sturdy. Don’t forget to make sure that all of the surfaces have been oriented properly and that they are solid objects. Be aware that some of the surface orientations may have changed from what they originally were drawn as.

Once everything is ready print the two halves.

Making the actual mold is super easy since all of the prep work was already done earlier in the drawing phase of making the master mold. All you have to do is mix your mold making material and pour it into the master molds.